Undersized radiators are a bad idea for heat pump systems

When radiators are too small, your heating system is forced to work harder than it should, or the room doesn’t get properly warm. To reach the same heat output, the system must push more water through the radiator - often much more. That means higher flow rates, more noise, and rising running costs. Oversized radiators, on the other hand, whilst still not ideal, cause less of an issue. This makes correct radiator sizing (and using the right balancing valves) especially important in low-temperature systems like heat pumps.

The Hidden Impact of Radiator Sizing

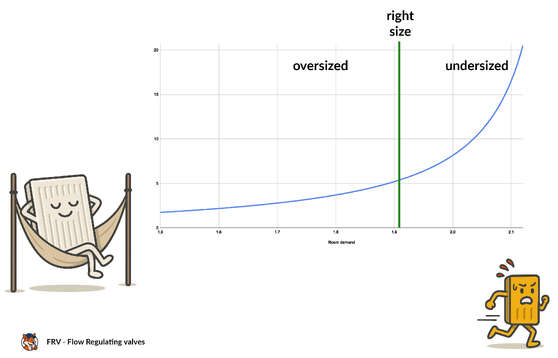

Most of us think of radiator sizing as a simple choice: a bit larger or smaller won’t make much difference. But the numbers tell a different story.

The chart below shows how an incorrectly sized radiator affects the required flow rate to achieve a target heat output at a fixed flow temperature. In this example, the radiator is rated at 1.9 kW at T5 and a 45 °C flow temperature - typical for a heat pump system.

If the heat demand drops to 1.5 kW, the required flow rate decreases by around 66 %. But if demand rises slightly to 2 kW, the required flow rate increases by roughly 66 %. That’s a dramatic jump for a small change in output.

Why Undersizing Is the Real Problem

Oversizing a radiator usually means it runs at a lower mean water temperature (MWT), which isn’t a problem - it can even improve efficiency. But undersizing is a different story.

In a low-temperature system, such as one served by a heat pump, the T (temperature difference between flow and return) is already small - often around 5 K. If the radiator can’t deliver enough heat, the only way to raise its output is to increase the flow rate to raise the MWT. However, at T5, there’s very little room to do that. The flow rate quickly becomes impractically high. This makes balancing increasingly tricky, can lead to noisy pipework, extra pump strain, and system inefficiency.

The next “fix” people might try is often to increase the flow temperature, but that defeats the purpose of a low-temperature system. Higher flow temperatures mean lower COPs (Coefficient of Performance) and higher running costs.

Balancing the Smart Way

The lesson is simple: get the radiator sizing right from the start. A correctly sized radiator allows the system to work at its designed temperature and flow rate - quietly and efficiently. Software like Heat Engineer, Spruce, H2X, Heatpunk and others make this a streamlined process for heating engineers by producing a full radiator schedule. This is very handy for use when balancing because the radiator outputs can be easily converted to the required flow rates. If you follow the link to our FRV valves at the bottom of this page then the instruction leaflet there shows you how to do this.

Once the right radiators are fitted, balancing them properly is the key to consistent performance. That’s where FRV valves come in. FRVs (Flow Regulating Valves) make fine-tuning flow rates quick, accurate, and repeatable - without endless trial and error. The result is a system that’s properly balanced and operating at peak efficiency.

Takeaway

Oversizing: mild effect.

Undersizing: major effect, especially in heat pump systems.

Correct sizing + FRV balancing = stable, comfortable, lower running cost.

If you’re upgrading to a heat pump, or re-balancing an existing system, take the time to check radiator sizing and flow rates. It’s one of the simplest ways to improve efficiency and reliability across the whole system - as long as you're using our FRV valves of course!

Ask a Question